Pet food processing line

Pet food production line is assigned to pet food with innovative shapes,unique taste and color,and to scientific nutrition proportion and easy to digest and other features to adapt to the constantly evolving pet food market. Taste of varied shapes and meet the needs of all kinds of pet food. Pet food production line by mixing powder, double screw extruder, air machine, drying and seasoning line composition.

Keywords:

Category:

- Description

- Application

- Features

- Technical Paramter

- Transportation

-

- Commodity name: Pet food processing line

Pet food production line is assigned to pet food with innovative shapes,unique taste and color,and to scientific nutrition proportion and easy to digest and other features to adapt to the constantly evolving pet food market. Taste of varied shapes and meet the needs of all kinds of pet food. Pet food production line by mixing powder, double screw extruder, air machine, drying and seasoning line composition.

Dog food/treats whole production line ,dog/cats food processing machine line ,pet food production line

Pet food production line is assigned to pet food with innovative shapes,unique taste and color,and to scientific nutrition proportion and easy to digest and other features to adapt to the constantly evolving pet food market. Taste of varied shapes and meet the needs of all kinds of pet food. Pet food production line by mixing powder, double screw extruder, air machine, drying and seasoning line composition.

Flow chart :Raw material---mixing—conveyor---extrusion –conveyor---drying –screening ---oil sprayer –seasoning—cooling-packaging

Machine list :Mixer ---conveyor ---double screw extruder---conveyor/elevator—multi-layer dryer ---- vibrating screen—elevator –oil sprayer—seasoning machine—cooling conveyor machine—packing machine

How to process :

Flour mixer : According to the different output of the production line, different models of mixers are used

Conveyor : The motor is used as the power screw conveying to ensure convenient and fast feeding

Extruder : According to the different output of the production line, different models of extrusion machine are selected, corn flour, bone meal, cereal flour, meat meal, etc. can be used as raw materials, and the specific product shape can be replaced by molds.

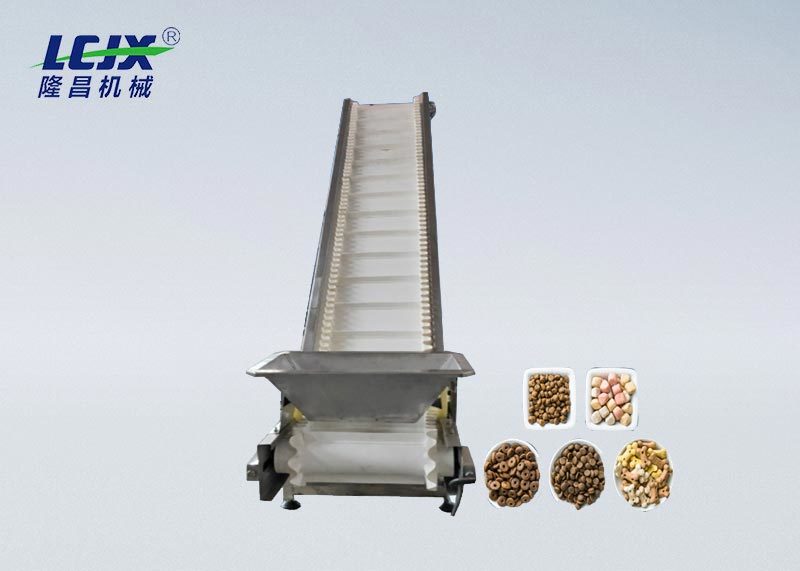

Elevator : Transfer the feed to the oven/dryer

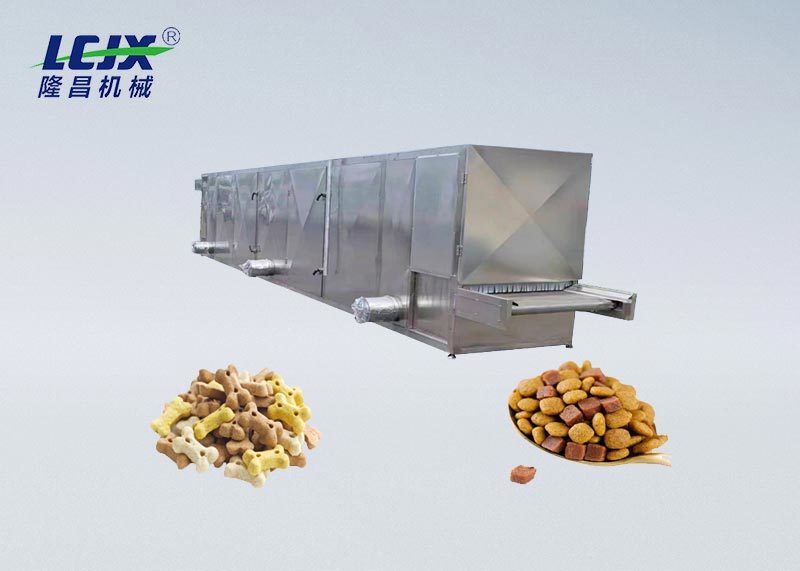

Multi-layer dryer : The dryer is an electric type, the temperature is controllable and adjustable between 0--200°, the internal use of stainless steel double-layer mesh belt, drying time can be randomly adjusted according to the conveying speed, according to the output, material properties are divided into three-layer, five-layer, seven-layer stainless steel dryer.

Vibrating screen : The crushed material is sieved out and can be reused as raw material to save costs

Seasoning line : There are octagonal cylinders, single drum/double drum seasoning lines, etc., which can be configured according to the output and product properties

Cooling conveyor : While ensuring product quality, the excess external sprinkling, grease, etc. on the surface of the material is filtered out to save the utilization of external sprinkling.

Service supply :

1. Provide all kinds of basic formulas

2. A variety of shapes available

3. Free installation and debugging

4. Responsible for personnel training

5. Free warranty for one year

-

-

Advantages of pet food production line

1. Precise control of process parameters and automation to ensure optimized particle quality: gelatinization, expansion, texture and consistent quality. These quality standards can be achieved because the screw ensures uniform processing and forward pumping. The processing of viscous paste does not depend on the friction between the screw and the barrel. The embedded automatic temperature control and adjustment system, modular screw configuration and screw speed are easy to program, which helps to improve the performance of the production line.2. Smart pet food extruder: recipe management (recording, access, supervision), process management (start/stop), installation of sensors, control and maintenance. Advanced production line automation helps reduce operating costs and promote consistent nominal production.

3. Creative shapes and finishing of products with innovative shapes and different textures (co-extrusion) by using special molds.

4. The composition is flexible, and various raw materials with high fat content can be processed when needed.

5. Use standard parts of extrusion and drying equipment to reduce maintenance and easy access to different machine components.

6. Specially designed by our expert engineers, with advanced automation functions, which can ensure accurate process control to achieve product quality that is easy to reproduce.

7. From 100 kg/h to 2000 kg/h.

-

Model

CW70

CW75

CW85

Power

380V/50HZ/60HZ

380V/50HZ/60HZ

380V/50HZ/60HZ

Installed Power

11OKW

220KW

200KW

Actual power consumption

70KW

160KW

140KW

Capacity per hour

180-250kg

600-800kg

400-600kg

Total length of line

15m

25m

30m

Applicable raw materials

Corn, flour, wheat bran, fishmeal, shares, etc., as well as various grains

-

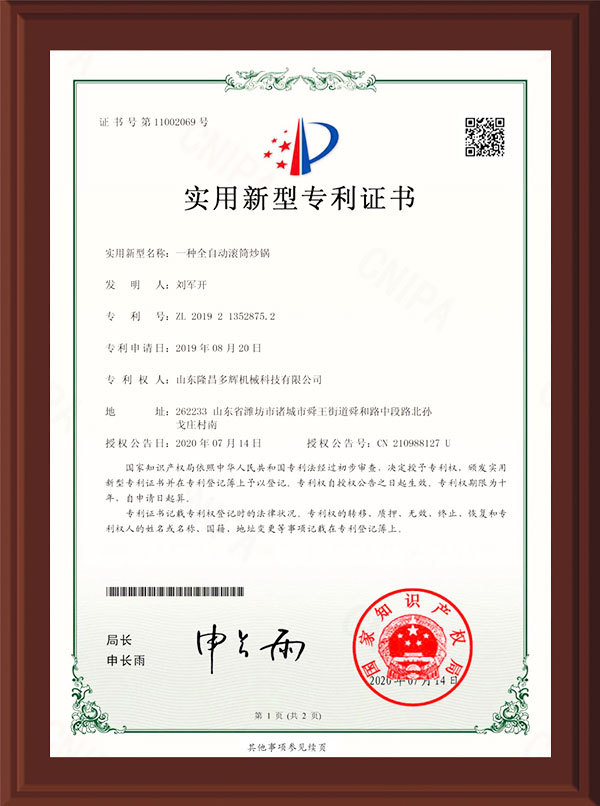

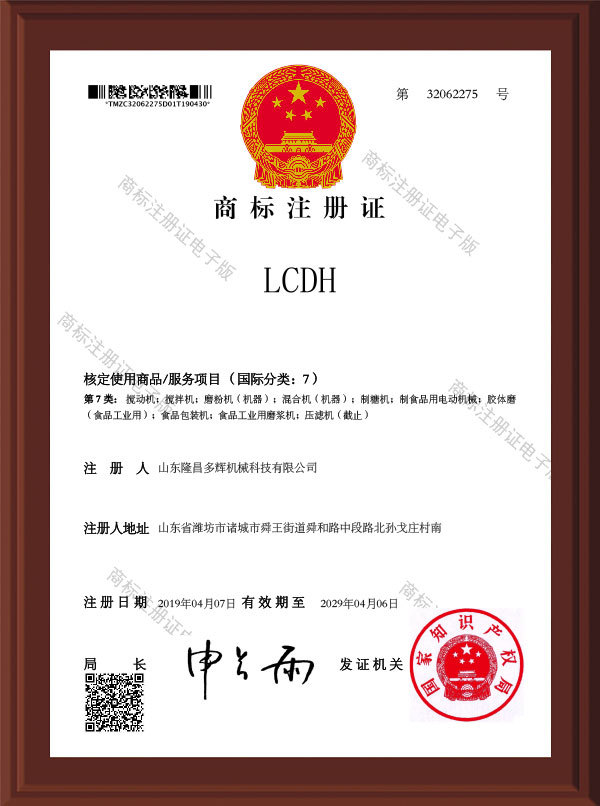

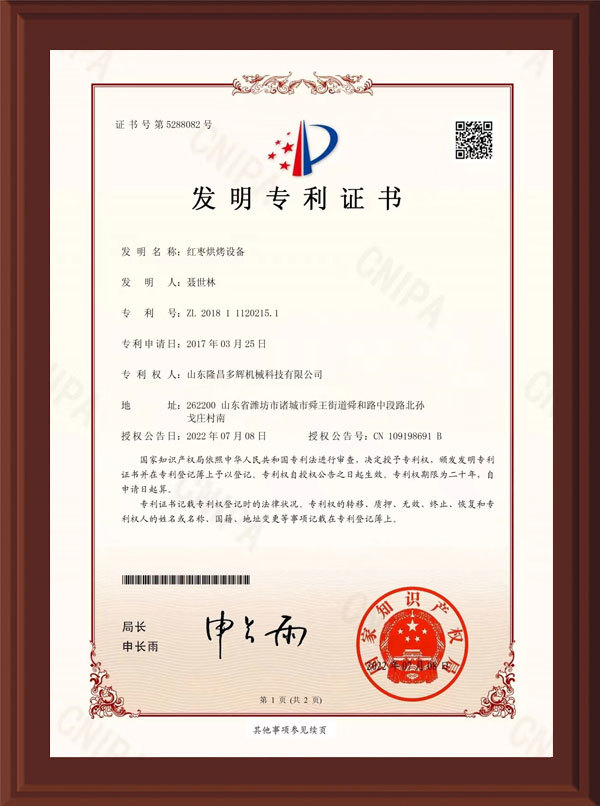

Qualifications

Trademark registration certificate

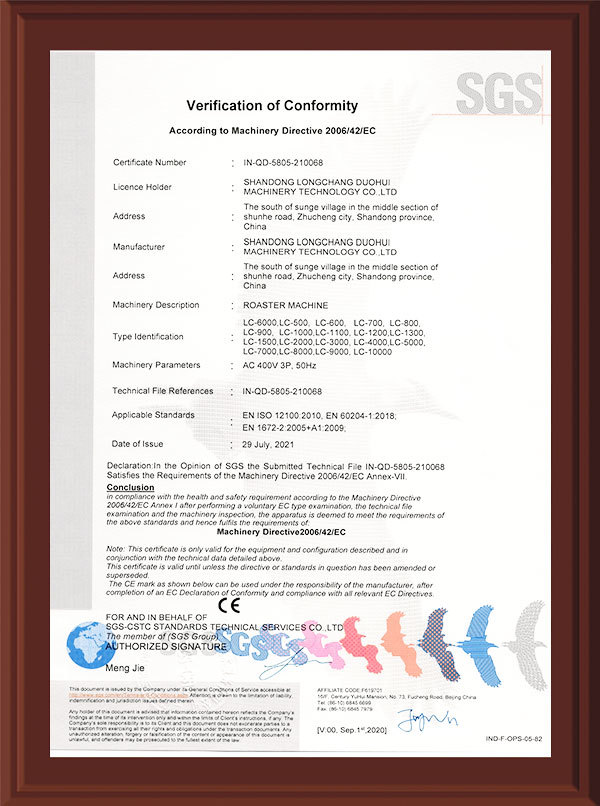

European Union CE

Utility model patent certificate

Appearance design patent certificate

Trademark registration certificate

Honor

Our Factory

Recommended Products

Online Inquiry